Anaerobic Co-Digestion System

At the heart of Dar Eco Circular’s Integrated Waste Facility (IWF) lies the

Anaerobic Co-Digestion (ACoD) System—a fusion of advanced Mechanical-Biological Treatment (MBT)

and BTA® anaerobic digestion technology. This system turns organic waste and faecal sludge into

clean energy, fertilizers, and industrial inputs, transforming Dar es Salaam’s waste crisis into

a launchpad for climate resilience, green industry, and food security.

🌍 Introduction to Integrated Biological Systems

Dar es Salaam faces overloaded landfills, untreated sludge, and minimal recycling.

The ACoD System introduces Urban MBT + Co-Digestion Hubs, powered by proven German technology,

designed for modularity and scalability across Africa.

- 🚫 Diverts 80–90% of organics away from landfills

- 🌱 Avoids 3.5 million+ tCO₂e annually by capturing methane

- ⚡ Generates renewable biogas, RDF, and fertilizers

- 🏘️ Frees up 130+ acres of urban land at Pugu for housing & greenspace

- 🌍 Positions Dar es Salaam as an African leader in circular infrastructure

♻️ Mechanical-Biological Treatment (MBT)

Technology Partner: Eggersmann Group (Germany)

Eggersmann’s FUEL® and CONVAERO® systems stabilize organic waste, recover recyclables, and produce

Refuse-Derived Fuel (RDF) for industries like cement and WtE.

System Workflow

- Pre-shredding & volume reduction

- Aerobic drying in CONVAERO® tunnels

- Optical & magnetic sorting for recyclables

- RDF production for industry

- Stabilized compost feedstock for co-digestion

✅ Enables fossil fuel substitution, ✅ reduces landfill emissions by 90%,

✅ reclaims sites like Pugu Landfill for housing.

⚡ Anaerobic Co-Digestion (ACoD)

Technology Partner: BTA International GmbH (Germany)

Using wet digestion + Thermal Hydrolysis (THP), BTA’s technology co-digests food waste, sludge,

and effluents to deliver high biogas yields and pathogen-free biosolids.

System Workflow

- Wet Pre-treatment: grit removal & homogenization

- Anaerobic Digestion: sealed digesters capture biogas

- Biogas Use: CHP, CBG for buses, grid injection

- Digestate Use: fertilizer, soil conditioners, green bricks

🌱 Value: Turns sludge into fertilizer, supports food resilience, reduces fuel imports, and

strengthens sanitation in flood-prone zones.

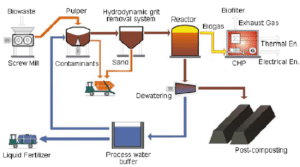

🔬 The BTA® Anaerobic Co-Digestion Process

The BTA® Process is at the heart of Dar Eco Circular’s Anaerobic Co-Digestion System, representing one of the most advanced biological waste treatment solutions globally.

At its core, the process consists of two essential stages:

-

Hydro-mechanical pre-treatment → Separates contaminants (plastics, metals, inerts) and homogenizes organic waste into a clean suspension suitable for digestion.

-

Wet Anaerobic Digestion → The pre-treated suspension is fed into sealed digesters where biogas is generated under controlled mesophilic or thermophilic conditions.

Yet, a full-scale BTA® Plant incorporates further critical processes to maximize efficiency, stability, and sustainability:

-

Solid–Liquid Separation → Digestate is separated into a nutrient-rich liquid fraction (for fertilizer and irrigation) and a stabilized solid fraction (usable as compost, soil conditioner, or construction input).

-

Process Water Management → Internal water recycling minimizes fresh water demand, reduces effluent discharge, and ensures closed-loop resource use.

📊 See Fig. 1 for schematic representation of the BTA® Process.

🎥 Watch the BTA® Process in Action

Together, these steps enable the conversion of complex waste streams—including food waste, faecal sludge, and high-COD industrial effluents—into renewable energy, fertilizers, and safe biosolids, while ensuring high environmental performance and alignment with IFC and AfDB sustainability standards.

🏗️ Deployment Model: Circular Infrastructure Anchors

| Facility | Municipal Zone | Core Tech | Functions |

|---|---|---|---|

| Pugu Kinyamwezi | Ilala/Temeke | MBT | Landfill reclamation, RDF, compost |

| Vingunguti | Ilala/CBD | ACoD | Septage digestion, mini-grid biogas |

| Pemba Mnazi (SEZ) | Kigamboni | MBT + ACoD + WtE | Industrial RDF, THP, fertilizer hub |

⚡ Modular, scalable, and aligned with SEZ & Smart City plans.

🌐 Global Benchmarking & Local Innovation

Global Inspiration

- 🇫🇮 Lohja, Finland → ACoD of MSW & sludge → inspires Pugu landfill reclamation

- 🇸🇪 Skövde, Sweden → Biogas + WtE district heating → informs Vingunguti hub

- 🇮🇶 Ecocem, Iraq → RDF via Eggersmann MBT → guides Pemba Mnazi industrial feed

Dar’s Local Innovations

- 📦 Containerized ACoD modules for dense zones

- ⚡ Mini-grid integration with surplus biogas

- 🌱 Urban biofertilizer loop → supporting urban farms & agroforestry

🌟 Strategic Benefits

- Climate: 3.5M+ tCO₂e avoided annually; carbon credit ready

- Energy: Biogas & CBG offset LPG/diesel imports

- Food Security: 20,000+ tonnes/year of local fertilizer

- Urban Resilience: Land reclaimed for housing & greenspace

- Industry: RDF replaces coal, biosolids → bricks

- Jobs: 1,000+ green jobs & SME opportunities

🚀 From Crisis to Catalyst

The Anaerobic Co-Digestion System is more than waste treatment—it’s a

visionary leap for Dar es Salaam. By combining MBT, ACoD, and WtE, the city will:

- Divert 85%+ of organic & recyclable waste

- Generate 8+ MW of renewable energy

- Produce 20,000+ tonnes/year of biofertilizer

- Unlock land for 10,000+ urban households

- Create thousands of dignified green jobs

🌍 With Dar Eco Circular, waste is no longer a liability—it’s a catalyst for innovation,

equity, and climate resilience.